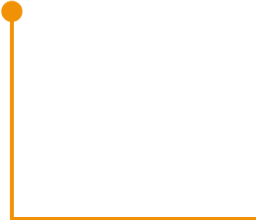

Follow the steps

To the disruptive and innovative solution.

Introducing

Swiss Technology

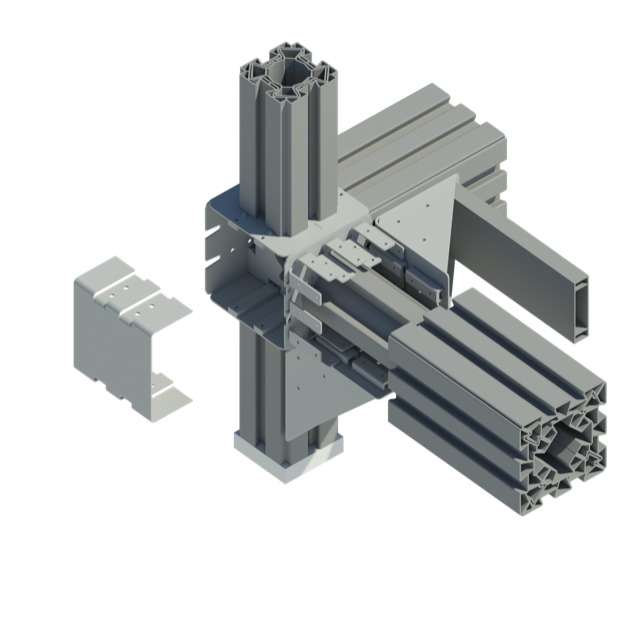

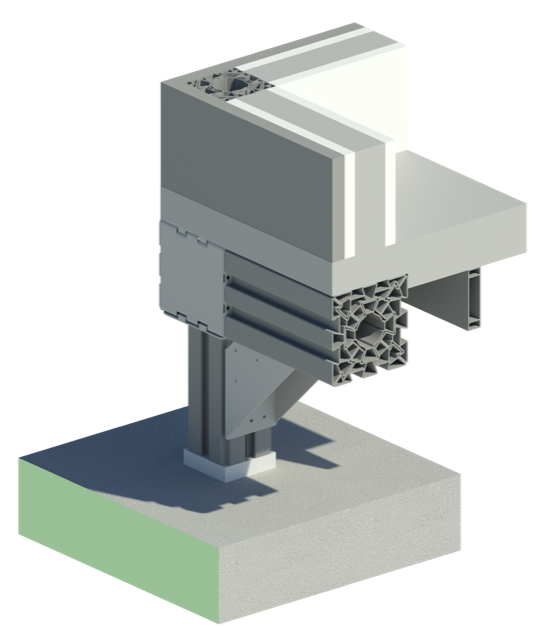

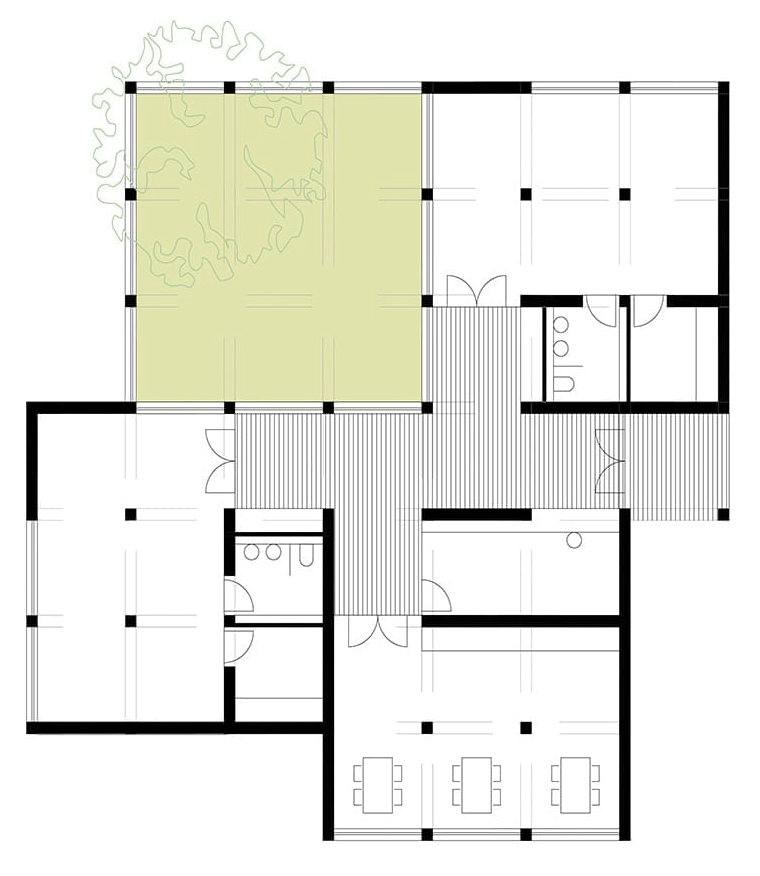

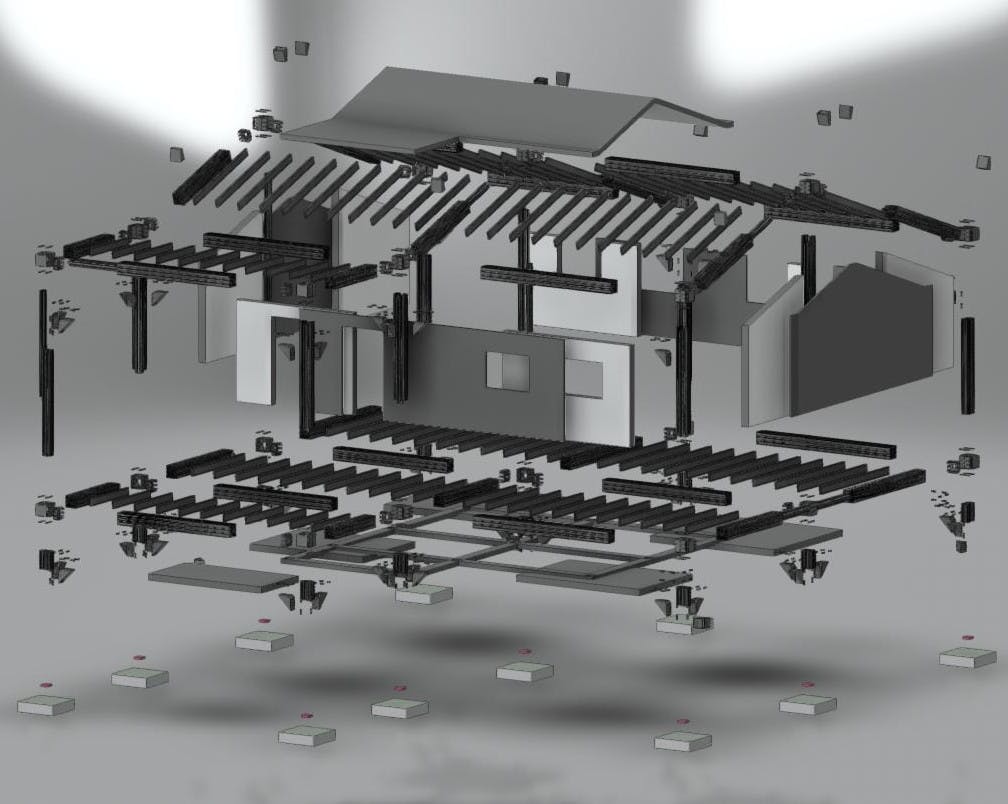

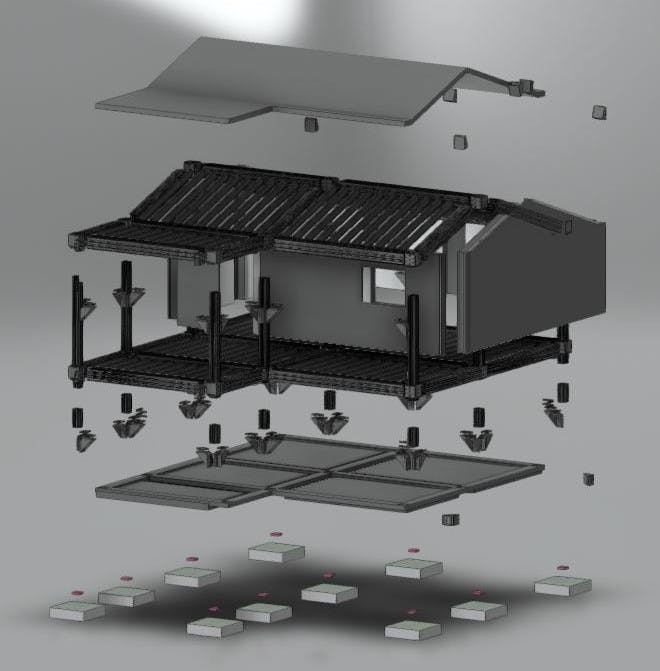

The patented modular UHCS design, established with only 5 main extruded profiles and their dedicated fasteners that assemble easily into a standard UHCS system for housing and/or into a light UHCS system usable for all sorts of lighter fixtures and one floor constructions.

Binding pieces from recycled metals

- No adhesives required for production and assembly

- 80% less CO2 emissions per kilogram of UHCS composite in comparison with concrete

- Zero-waste production process

- No specialized labor required

With distinctifs materials

It is easier to reintegrate

A construction in composite poles and beams and detachable connectors

all designed to enable easy disassembly.

the cycle

recycled steel

fiberglass

recycled PET

It’s about the art of omitting and about extending

the value of our products. In the UHCS construction modules

we use as many materials as possible that are already recycled

PET - polyethylene

terephthalate

PET

PET

PET (polyethylene terephthalate) is a synthetic material be-longing to the polyester family. It is obtained from crude oil, natural gas or bio-vegetal raw materials. PET is 100% recyclable and in principle dose not lose its fundamental characteristics as it can be now eternally regenerated and can therefore be reused many times over to produce higher quality products. We have chosen it as our basic material for its mechanical and structural properties, and its high recyclability.

The making of a new necessities with recycled PET saves up to 50% of the energy required for primary PET production. R- PET can now eternally continue to serve mankind’s basic needs: food & beverage, water distribution, clothing, medical hygiene (proven effect against malaria) , sanitation, furniture, and now not the least: housing thanks to the UHCS solution. Thus, all with a very reduced impact on nature when not misplaced!

In 2020, the global demand for PET was 27 million metric tons. By 2030, global demand for PET is expected to be 42 million metric tons. To date, less than 10% of its annual production is recycled compared to 83% recycled in Switzerland. We will certainly not lack raw materials.

Disruption in Construction

1. Extrude and produce

Poles, beams, fasteners and wall panels are produced in a local factory or sourced from our strategic partners

2. Design

Let us design your next-generation modular home

3. Assemble

All elements are shipped to your site, where foundations and utility systems are ready in advance. The structure, roof, walls and systems are completed, shell-and-core for you to further customize the home of your dreams.

4. Home

5. Disassemble

Initial design and assembly instructions plan for disassembly, dismantling and further recycling or re-using of your UHCS modular home.

UHCS Solution

Benefits

Endless architectural possibilities during construction and over time

Scalable production

Easy assembly and disassembly

Efficiency at all stages of the construction system

Circular production with limited residual waste

Reduced carbon footprint

Expanded access to housing and house ownership

Involvement of the regional economy

Our partners &

multinational suppliers

2023 UHCS CONSTRUCTIONS SA. All Rights Reserved.